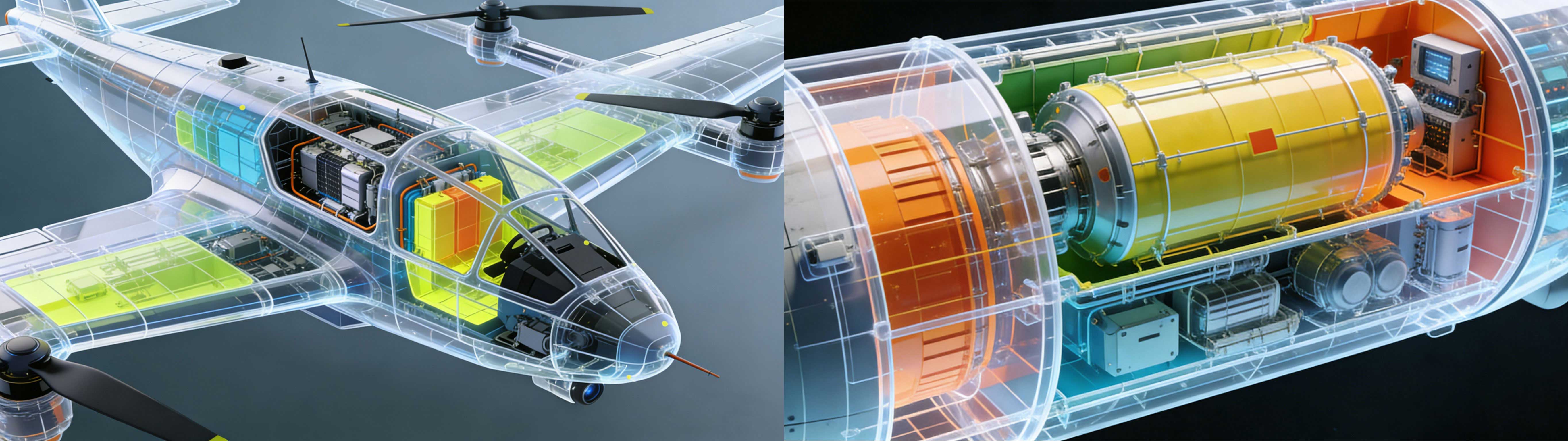

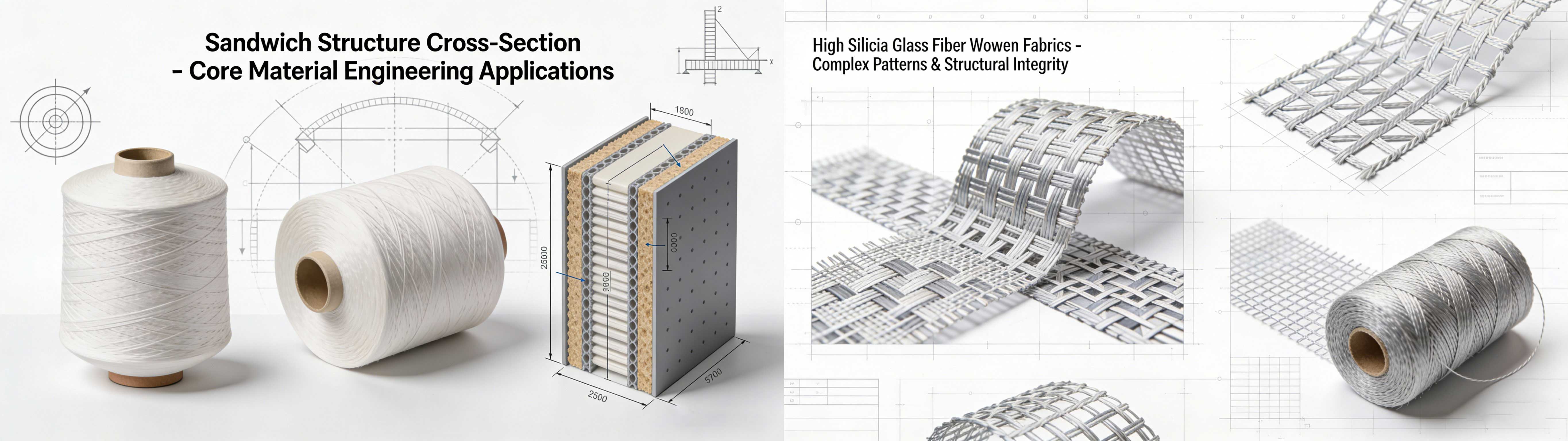

This technical article explores the application of high-silica fiberglass yarn (HSF, SiO₂ ≥ 96%) as a critical material for thermal & electrical insulation in aerospace & unmanned aerial vehicle (UAV) systems. The analysis focuses on non-propulsive components, specifically power compartments & internal/external structural insulation. A comparative assessment against aramid & carbon fibers is presented, evaluating key parameters such as operational temperature, dielectric strength, mechanical strength, density, and cost-effectiveness. Material selection matrices are proposed for various operational scenarios.

Modern aerospace and UAV design demands lightweight, reliable, and high-performance insulation materials to protect sensitive avionics, battery systems, and structural components from extreme thermal and electrical environments. High-silica fiberglass yarn emerges as a versatile candidate, balancing excellent thermal resistance with inherent electrical insulation properties.

Primary Function: Contain thermal runaway events, prevent heat propagation to adjacent structures, and provide electrical isolation.

Key Requirements: High temperature resistance (short-term exposure up to 1000-1200°C), excellent dielectric strength, low thermal conductivity, and flame retardancy.

Operational Environment: Potential for rapid temperature spikes, presence of high-voltage components.

Primary Function: Shield flight control computers, wiring harnesses, and sensors from ambient heat (e.g., from skin friction, engine bay radiant heat).

Key Requirements: Continuous operating temperature resistance (~500-700°C), effective thermal barrier, vibration damping, and low out-gassing.

Operational Environment:Moderate but sustained temperatures, need for long-term reliability.

Primary Function:Protect composite air-frames from aerodynamic heating, exhaust plume impingement (for UAVs with rear-mounted engines), & lightning strike effects.

Key Requirements:Good mechanical abrasion resistance, weathering stability, combined thermal and electrical insulation, and adhesion to composites.

Operational Environment:Exposure to varying atmospheric conditions, UV radiation, and potential mechanical wear.

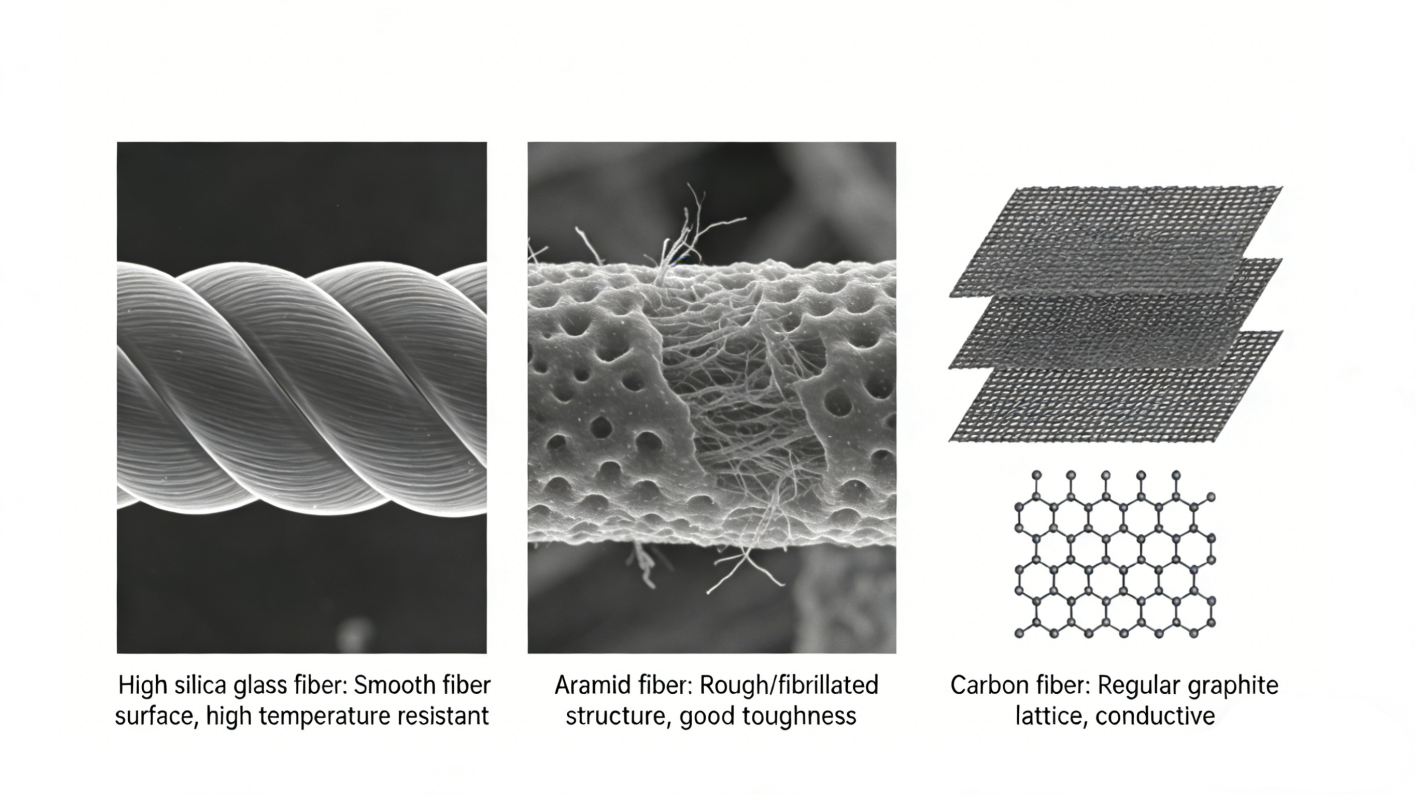

The following table compares the fundamental properties of High-Silica Fiberglass (HSF), Aramid, and Carbon Fiber relevant to insulation applications.

| Property | High-Silica Fiberglass (HSF) | Aramid (e.g., Kevlar®) | Carbon Fiber |

|---|---|---|---|

| Max Continuous Use Temp. | ~1000°C | ~250-350°C | ~400-500°C (in inert atm.) |

| Short-Term Peak Temp. | Up to 1200°C | Degrades above 450°C | Oxidizes above 500°C |

| Dielectric Strength | Excellent (High Insulator) | Good | Conductive (Not an Insulator) |

| Tensile Strength | Good | Excellent | Exceptional |

| Density | ~2.2 g/cm³ | ~1.44 g/cm³ | ~1.6-1.8 g/cm³ |

| Thermal Conductivity | Very Low | Low | High (along fiber axis) |

| Primary Advantage | Best combined high-temp & electrical insulation | Best mechanical toughness & impact resistance | Best stiffness & strength-to-weight |

| Key Limitation | Brittle compared to aramids | Poor UV and high-temp stability | Electrically conductive, oxidizes at high temp |

Remark:The data is based on Lab testing conditions, the adjustment shall be done as per application environment

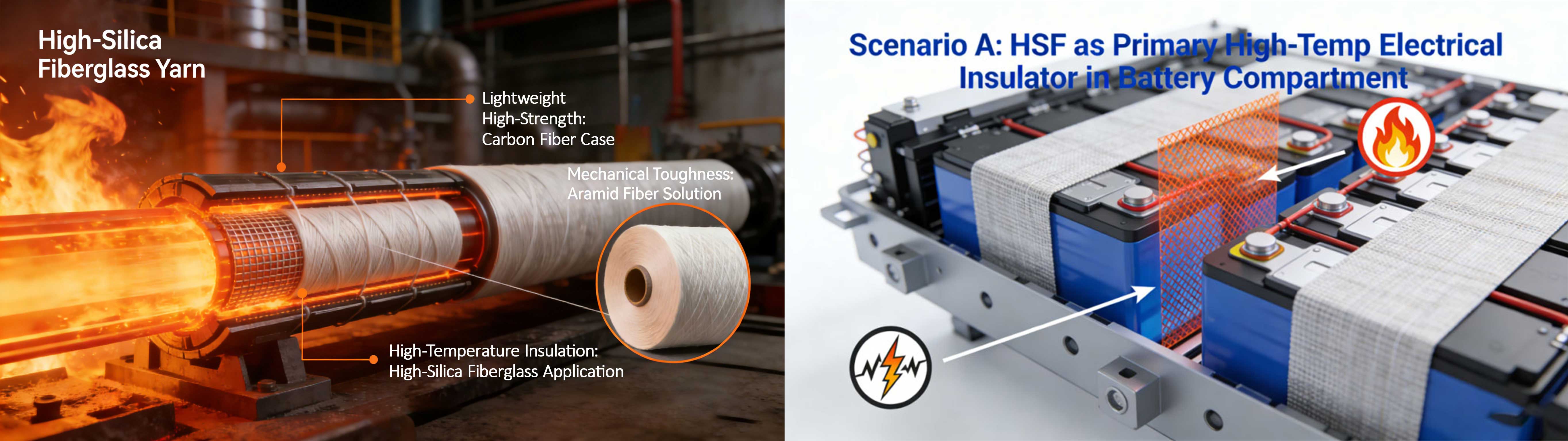

Selection is driven by the primary threat (heat, electricity, impact) and specific location requirements.

Threat: High voltage + potential arc flash / thermal event

Solution: HSF Alone. Its superior and stable dielectric strength at elevated temperatures is unmatched. Neither aramid (lower temp limit) nor carbon (conductive) are suitable as primary insulators here.

Threat: Mechanical abrasion/vibration + moderate heat.

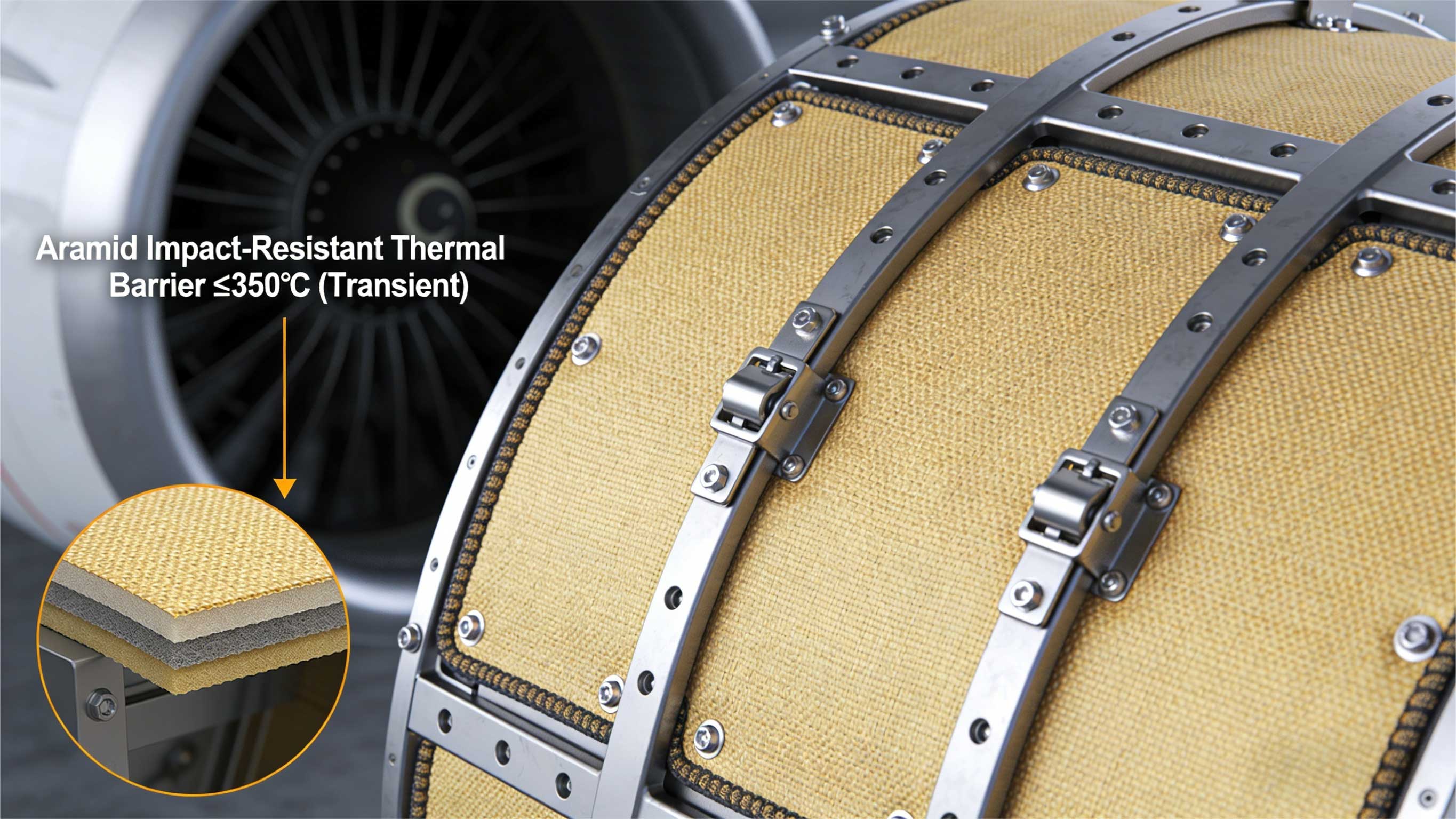

Solution: Aramid Alone or Aramid/HSF Hybrid.Use aramid fabrics where toughness is paramount below 350°C. For higher temperatures, a hybrid fabric with an aramid base for strength and an HSF surface layer for thermal protection can be optimal.

| Component | Temperature Range | Primary Application | Structural Suggestion |

|---|---|---|---|

| Engine Nacelle / Pylon Thermal-Acoustic Insulation Liner | ≤ 250°C | Impact resistance, thermal insulation, noise reduction | Aramid fabric + flame-retardant matrix, layered composite |

| Fuselage / Wing Leading Edge Bird Strike & Thermal Protection Layer | ≤ 200°C | Impact resistance, anti-icing, thermal insulation | Aramid fabric sandwich, co-bonded/cocured with skin |

| Cabin Firewall / Thermal Barrier | ≤ 200°C | Fire containment, thermal insulation, impact resistance | Aramid non-woven / fabric + flame-retardant adhesive film |

| Rocket Body Cryogenic and Impact Protection Layer | -196°C to 200°C | Cryogenic toughness, impact resistance, thermal insulation | Aramid fabric + cryogenic-compatible matrix |

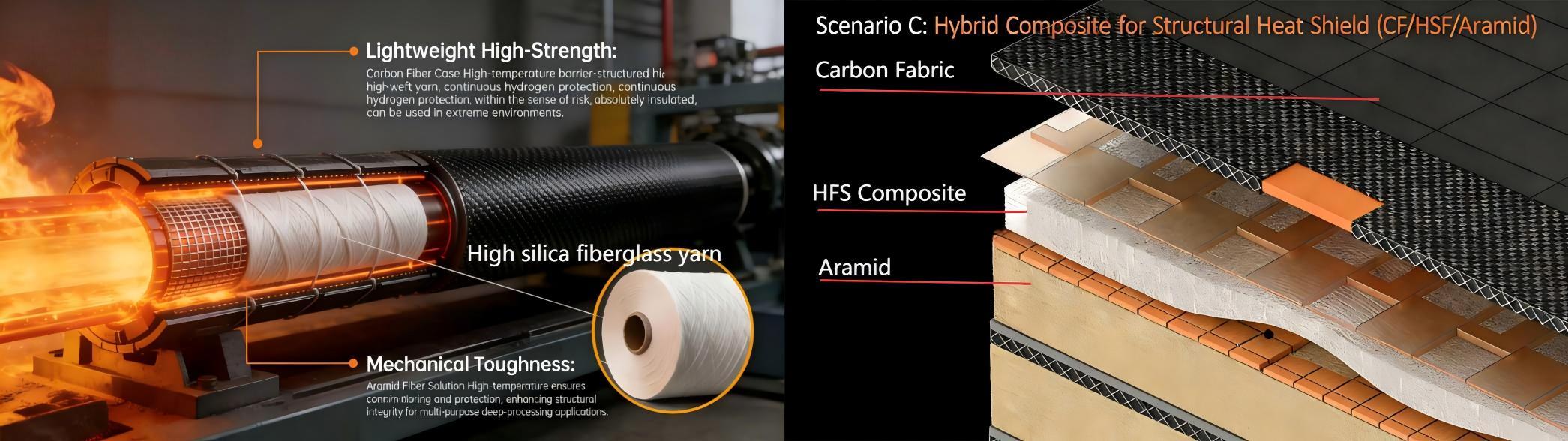

Threat: Aerodynamic heating + need for structural rigidity.

Solution: Carbon Fiber/HSF Composite.A laminate with carbon fiber providing structural stiffness and an HSF layer as the thermal barrier. This separates the load-bearing function from the insulation function efficiently.Note:An insulating layer must separate carbon from any electrical components.

Threat: Radiant and convective heat, need for flexibility and low mass.

Solution: HSF Alone.Offers the best balance of high-temperature capability, low thermal conductivity, and electrical safety in a lightweight, flexible fabric form.

High-silica fiberglass yarn is not a universal replacement for aramid or carbon fiber but a specialized material that excels in the niche where high-temperature resistance and electrical insulation are simultaneously required.In aerospace and UAV insulation design:HSF is the default choice for primary thermal-electrical insulation in power systems and high-temperature zones.

Aramid is selected where impact resistance and toughness are critical at lower to moderate temperatures.

Carbon Fiber is integrated into structural heat shields where stiffness is a driver, but always paired with an insulating layer like HSF.

The future lies in engineered hybrid composites (e.g., HSF/aramid weaves, HSF as a core in carbon sandwich panels), which allow designers to tailor material systems to meet the multifaceted demands of next-generation aerospace vehicles, optimizing for weight, performance, and safety.

| Comparison Dimension | Silica Fiberglass | Silica Yarn (High-Silica Yarn) |

|---|---|---|

| Core Definition | Base Material Category. Refers to any glass fiber with silica (SiO₂) as the main component (>50%). | Finished Product Form. Specifically refers to continuous yarn made from high-purity silica fibers (SiO₂ ≥ 96%) via twisting/plying processes. |

| Composition and Process | Broad composition range (e.g., E-glass: ~52-56% SiO₂, C-glass: ~65%). Made by melting and drawing. | High-purity specific. Made by acid-leaching special glass fibers to remove metal oxides, boosting SiO₂ to 96%-99%+, then spun into yarn. |

| Performance Focus |

Properties vary by type: • E-glass: General purpose, good insulation & strength. • C-glass: Acid-resistant. • S-glass: High strength/modulus. |

Performance optimized for extreme conditions: • Ultra-high temp resistance (1000°C+ continuous). • Minimal thermal conductivity (superior insulation). • Excellent dielectric strength. • High chemical stability (except HF/strong alkalis). |

| Physical Form |

Primary forms: • Continuous rovings • Chopped strands • Woven fabrics/mats (made from rovings) |

Specific yarn form: • Singles or plied yarns • Defined yarn count (Tex, Denier) • Ready for weaving, knitting, sewing |

| Primary Applications |

Wide-ranging, as reinforcement/functional material: • Composite reinforcement (FRP) • Insulation substrate • Filtration media • Building insulation wool |

Focused on high-end insulation: • High-temp industrial blankets/sleeves • Firefighting gear, curtains, blankets • Aerospace thermal protection • High-temp sealing/wrapping |

| Analogy | Like "Steel" – a broad material category with many grades. | Like "Stainless Steel Wire of a specific grade" – a finished product form for specific applications. |

HSF vs. Aramid/Carbon: HSF excels where both extreme heat resistance and electrical insulation are required simultaneously. It is not a direct replacement but a specialized solution.

Material vs. Product:"Silica Fiberglass" is the general material name; "Silica Yarn"(or"High-Silica Fiberglass Yarn") refers specifically to the high-purity, yarn-form product ready for demanding insulation applications. In aerospace contexts, the latter is typically the subject of discussion.

Note on UAV Terminology:

In this article,"UAV" (Unmanned Aerial Vehicle) is used as the standard technical term within the aerospace industry, emphasizing the vehicle as a complete system. Other common terms include "Unmanned Aircraft" (formal/regulatory) and "Drone" (general/public).

2nd Floor, No. 2 Standard Workshop, Hengke Industrial Park Phase I,Ganzhou Economy and Technology Development Zone, Ganzhou City, Jiangxi Province, P.R. China

赣公网安备36072402000211号

赣公网安备36072402000211号