Deeprotect™ Material specializes in the production of fireproof cloth series products using fire-resistant fiberglass fabric as the base material. Each production step involves precision equipment and process controls to ensure product quality.

The warping process prepares glass fiber yarns for weaving by aligning and treating them under controlled conditions:

Glass fiber yarn is processed using a Karl Mayer DS 21/30NC sectional warping machine at low speed (<200 m/min), with ionized air guns (humidity 40–60%, surface resistance ≤10⁹ Ω) to eliminate static electricity and ensure uniform yarn tension (5–20 cN, fluctuation ≤±2%).

Epoxy-based sizing agents (solid content 8–12%, temperature ≤60°C) are applied via a Benninger Sucker-Muller sizing machine, followed by curing with a Tsudakoma LHS-500 low-temperature dryer (80–120°C) to enhance yarn abrasion resistance while retaining ≥90% strength.

- Tension Uniformity: Online sensors monitor real-time tension deviation (≤±2%).

- Sizing Coverage: Microscopic inspection targets ≥95% film coverage.

- Beam Hardness: Shore hardness 60–80 tested post-winding.

Creel Loading → Warping (Karl Mayer DS 21/30NC) → Sizing (Benninger Sucker-Muller) → Drying → Beam Output

| Parameter | Specification |

|---|---|

| Warping Speed | ≤200 m/min |

| Sizing Temperature | ≤60℃ |

| Drying Temperature | 80–120℃ |

| Yarn Tension | 5–20 cN (±2%) |

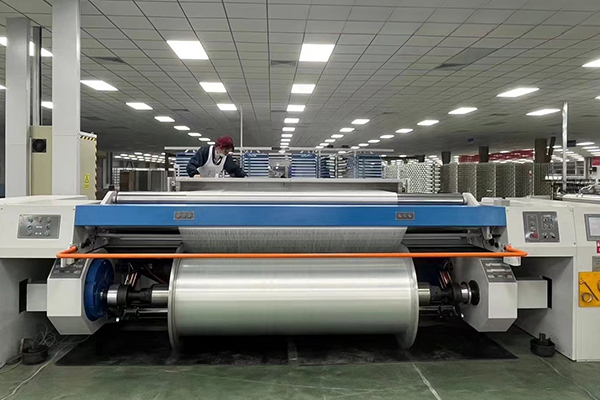

The weaving process interlaces warp and weft yarns into fabric with precision-controlled parameters:

- Rapier Loom (e.g., Picanol OMNIplus-X): Equipped with electronic let-off (EBC) and take-up systems to control tension fluctuation ≤±2%. Optimized for plain/twill weaves (weft density: 60–80 picks/inch) and fabrics weighing 300–800 g/m² at 400–600 rpm.

- Dobby Loom (e.g., Stäubli CX-860): Uses 16–24 lightweight heald frames for complex structures (e.g., 2/2 twill) in multi-layer fireproof composites.

- Special Applications: Shuttle looms with ceramic guides produce lightweight fabrics (<200 g/m²) at 30% lower efficiency than rapier looms.

- Warp Tension: 50–200 cN (adjusted by yarn tex).

- Shed Height: 10–30 mm to minimize fiber friction.

- Weft Insertion: 300–600 m/min (rapier), 1000–1500 m/min (air-jet).

- Real-time Monitoring: CCD cameras detect defects (hole, mispick) with ≤0.1% defect rate.

- Final Inspection: Fabric weight tolerance ±3% (ISO 3374), tensile strength tested per ASTM D5035.

| Parameter | Specification |

|---|---|

| Loom Speed (Rapier) | 400–600 rpm |

| Fabric Weight Range | 200–800 g/m² |

| Weft Density | 60–80 picks/inch |

| Tension Fluctuation | ≤±2% |

Tailored to fire resistance ratings (EN13501-1 Class A to B):

| Material | Temperature Resistance | Applicable Products | Coating Process |

|---|---|---|---|

| Silicone Rubber | 300–800°C | Fire Blankets, Curtains | Blade Coating (0.2–0.5 mm) |

| Ceramic Sol-Gel | 800–1200°C | Industrial Pipe Wrapping | Spray Coating (Porosity <5%) |

| Vermiculite Composite | 600–1000°C | Architectural Fire Screens | Impregnation (≥50% Pickup) |

Monforts Thermex Continuous Impregnation Machine: Dual-side silicone coating with staged curing (120°C → 220°C).

Nordson EFD ProSeries Spray Coater: Nano-ceramic coating with ±5 μm precision.

| Coating Type | Equipment | Thickness Range | Temperature Resistance |

|---|---|---|---|

| Silicone Rubber | Monforts Thermex | 0.2-0.5 mm | 800°C |

| Ceramic Sol-Gel | Nordson EFD ProSeries | 10-30 μm | 1200°C |

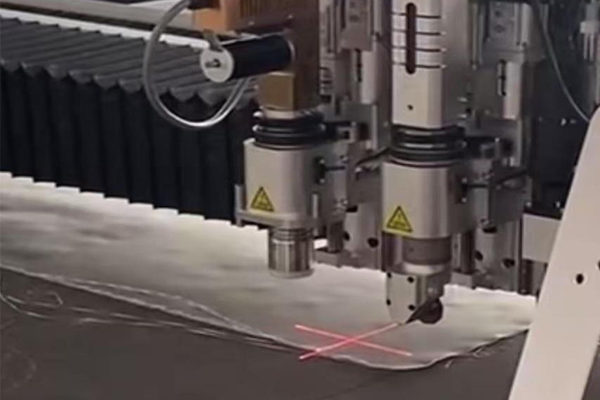

- Precision Cutting:Trumpf TruLaser 5030 laser cutter (500W power) handles complex contours with edge carbonization depth <0.1 mm.

- Bulk Slitting:Eastman E91 rotary blade cutter (blade angle: 15°) achieves high-speed slitting at 30 m/min

- High-Speed Double-Needle Lockstitch:JD-4420D-457-18 industrial sewing machine (3000-3500 RPM) processes fireproof fabrics with 2.5-4.0mm adjustable stitch length, achieving seam strength ≥90% of base material.

- Precision Single-Needle Stitching:JACK A4B & A4 direct-drive machines (3500-4000 RPM) with titanium-coated GDx1 needles (size #14-18) and ±0.5mm stitch positioning accuracy.

- Programmable Curved Seams:BAND single-needle stepper machine with 0.1mm precision for complex fireproof garment contours.

- High-Temp Fastener Attachment:WT automatic system installs 300-500 composite fasteners/hour with ±0.3mm positioning accuracy.

- Thread Material: Aramid/PBO fibers (600-1200D, LOI ≥30)

- Needle Specification: Titanium-coated GDx1 (size #14-18)

- Tension Range: 15-25N calibrated

| Parameter | Standard | Test Method |

|---|---|---|

| Seam Strength | ≥90% base material | ASTM D1683 |

| Stitch Density | 6-8 stitches/cm | ISO 4915 |

| Thread Melting Point | ≥500°C | ISO 3146 |

- Ceramic-coated components minimize fiber abrasion

- Automated tension control ensures uniform stitching

- Needle temperature monitoring (≤120°C)

- PU/PVC Coating Process:Thermal curing at 180-220°C for 2-5 minutes with conveyor speed 0.5-2 m/min, achieving LOI ≥28.

- Vermiculite Coating Process:High-temperature treatment at 250-300°C for 3-6 minutes with controlled oxygen content below 5%.

- Pre-heating Zone:60-80°C for moisture removal (30-90 seconds)

- Primary Curing:Target temperature exposure (±2°C accuracy)

- Stabilization:150°C post-curing for 30 seconds

- Temperature Control: ±2°C accuracy

- Cooling Rate: 3-5°C/second

- Atmosphere: ≤5% oxygen content

| Parameter | Standard | Test Method |

|---|---|---|

| Thermal Stability | ≥500°C | ISO 3146 |

| Coating Adhesion | ≥3.5 N/mm² | ASTM D4541 |

| LOI Value | ≥28 | ASTM D2863 |

- Uniform heat distribution (±5°C across belt width)

- Automated temperature profiling

- Real-time oxygen monitoring

The printing system employs three distinct technologies to achieve durable markings and designs on fire-resistant materials. Each method is selected based on its compatibility with high-temperature substrates and regulatory requirements.

| Process | Equipment Combination | Applications | Technical Parameters | Precision |

|---|---|---|---|---|

| Screen Printing | M&R Chameleon + GEW E2C | Fire Labels/Warning Text | Silicone Ink (350°C Resistance) | ±0.3 mm |

| Thermal Transfer | Zebra ZT411 + HIX HT-400 | UL Certification Labels/QR Codes | Transfer Temp: 250°C, Pressure: 0.4 MPa | ±0.1 mm |

| Digital Direct Jet | Kornit Avalanche HD6 | Custom Logos (Fire Brigade Emblems) | 1200 dpi, 280°C Resistance | 1200 dpi |

- Pre-treatment:Surface cleaning and plasma activation (30-60 seconds)

- Ink Application:Technology-specific deposition methods

- Curing:Thermal or UV curing based on ink type

- Temperature Tolerance: ±5°C during curing

- Registration Accuracy: ≤0.3mm for multi-color prints

- Adhesion: ≥3B rating (ASTM D3359)

Our comprehensive packaging system ensures product integrity from factory to end-user, meeting strict environmental standards, functional requirements, and international import regulations.

- Inner Packaging:Vacuum-sealed bags (Multivac C350) with ≤0.5% residual oxygen and ≤30% RH moisture control, featuring anti-static lining for sensitive labels

- Outer Packaging:FSC-certified corrugated cardboard boxes with water-resistant coating and flame-retardant ink (REACH/ROHS compliant)

- Standard Shipments:Double-walled corrugated boxes (ECT ≥44) with edge protectors and stretch-wrapped pallets

- Bulk Shipments:ISPM 15 heat-treated wooden crates with VCI film and steel banding for pallet fixation

- Leak testing: ≤0.5% O₂ verification in vacuum bags

- Drop-testing: ISTA 3A compliant for parcel shipments

- Material compliance: REACH/ROHS, EN 13432, ASTM D4169

- Recyclability:100% plastic-free options available (kraft paper tapes, starch-based foam)

- Protection:Anti-UV film and ERGO-TECH® roll cores with ≤20 N/m² tension control

Note: All packaging is customizable for OEM/private-label needs.

| Product Type | Fire Rating | Tensile Strength | Standards Compliance |

|---|---|---|---|

| Industrial Fire Blanket | EN13501-1 A | ≥2500 N/5cm | GB/T 5455-2014 |

| Firefighter Outerwear | ASTM E84 A | ≥1800 N/5cm | NFPA 1971 |

Deeprotect prioritizes precision equipment for fire-resistant product manufacturing.

Our Picanol OMNIplus-X rapier looms ensure optimal fabric weaving - the foundation of tensile strength and structural integrity.

| Process | Equipment | Brand/Model |

|---|---|---|

| Weaving | Rapier Loom | Picanol OMNIplus-X |

| Coating | Nano Spray Coater | Nordson EFD ProSeries |

| Printing | Intelligent Screen Printer | M&R Chameleon |

- Weaving: Integration of Toyota Connected Weave System for loom-coating line data linkage.

- Printing:Deployment of M&R Intelligent Alignment System with AI vision for ±0.1 mm pattern accuracy.

Through rigorous process management, our fireproof cloth products meet EN13501-1, ASTM E84, and other international standards, serving diverse markets.

2nd Floor, No. 2 Standard Workshop, Hengke Industrial Park Phase I,Ganzhou Economy and Technology Development Zone, Ganzhou City, Jiangxi Province, P.R. China

赣公网安备36072402000211号

赣公网安备36072402000211号