High Purity Silica Fiberglass Yarn vs. High-Purity Quartz Yarn:

A Comparative Technical Analysis

By Technical Team-Deeprotect

1. Introduction

High-temperature-resistant yarns are critical in industries requiring thermal insulation, fire protection, and chemical stability. Two prominent materials in this category are high-silica fiberglass yarn (SiO₂ ≥ 96%) and high-purity quartz yarn (SiO₂ ≥ 99.95%). While both offer excellent heat resistance, they differ in composition, performance, and applications. This article explores their characteristics, advantages, limitations, and future trends.

2. Material Composition & Manufacturing

High-Silica Fiberglass Yarn

-

Composition: 96–99% SiO₂, with traces of Al₂O₃, CaO, and B₂O₃.

-

Production: Derived from acid leaching of E-glass fiber, removing metal oxides to increase silica content.

-

Structure: Amorphous (non-crystalline) silica, providing flexibility and tensile strength.

High-Purity Quartz Yarn

-

Composition: ≥99.95% SiO₂, with minimal impurities (Fe, Na, K < 50 ppm).

-

Production: Melt-spun from synthetic quartz crystals or natural quartz powder, requiring ultra-high temperatures (~2000°C).

-

Structure: Crystalline or fused silica, offering superior thermal stability but lower flexibility.

3. Key Properties & Performance Comparison

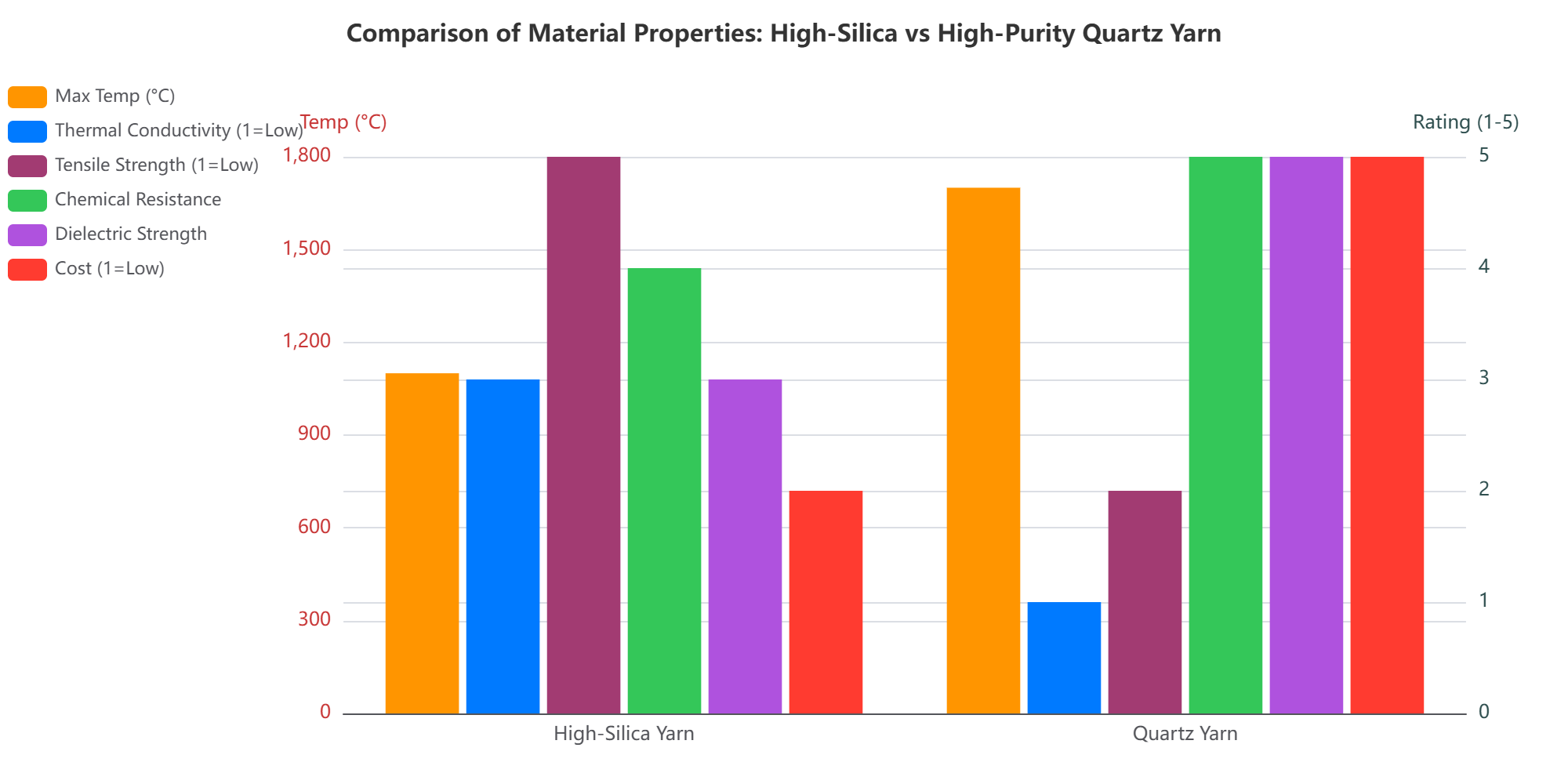

|

Property

|

High-Silica Fiberglass Yarn

|

High-Purity Quartz Yarn

|

|

Max. Temp. Resistance

|

1000–1100°C (short-term)

|

1600–1700°C (continuous)

|

|

Thermal Conductivity

|

~0.06 W/m·K

|

~0.04 W/m·K (lower)

|

|

Tensile Strength

|

High (flexible, weavable)

|

Lower (brittle)

|

|

Chemical Resistance

|

Excellent (except HF, alkalis)

|

Exceptional (inert to most chemicals)

|

|

Dielectric Strength

|

Good

|

Superior (high-voltage insulation)

|

|

Cost

|

Moderate

|

High (raw material & process)

|

Comparison of Material Properties: High-Silica Fiberglass Yarn vs High-Purity Quartz Yarn

4. Applications

High-Silica Fiberglass Yarn

-

Fire Protection: Fire blankets, firefighting suits, insulation for cables and pipelines.

-

Industrial: Welding protection, thermal shields in aerospace.

-

Consumer: Lightweight heat-resistant fabrics for outdoor gear.

High-Purity Quartz Yarn

-

Semiconductor: Wafer handling, furnace linings (low thermal expansion).

-

Aerospace: Rocket nozzles, re-entry vehicle insulation.

-

High-Tech Optics: UV-transparent components, laser systems.

5. Advantages & Limitations

High-Silica Fiberglass Yarn

✔ Pros:

-

Cost-effective for mass production.

-

Flexible and easy to weave into fabrics.

-

Good balance of thermal and mechanical properties.

✖ Cons:

-

Lower thermal stability vs. quartz.

-

Vulnerable to hydrofluoric acid and strong alkalis.

High-Purity Quartz Yarn

✔ Pros:

-

Exceptional thermal and chemical resistance.

-

Near-zero thermal expansion.

-

Ultra-high purity for critical environments.

✖ Cons:

-

Expensive due to complex manufacturing.

-

Brittle, limiting textile applications.

6. Future Trends

-

High-Silica Yarn: Demand growth in fireproof textiles (e.g., EV battery insulation).

-

Quartz Yarn: Expanding use in semiconductor and quantum computing industries.

-

Hybrid Solutions: Blending silica and quartz fibers for optimized cost-performance ratios.

7. Conclusion

While high-silica yarn dominates cost-sensitive, flexible applications, high-purity quartz yarn excels in extreme environments. Material selection depends on temperature requirements, budget, and mechanical needs. Advances in purification and fiber-spinning technologies will further differentiate their roles in high-tech industries.

Keywords: high-silica fiberglass, quartz fiber yarn, thermal insulation materials, high-temperature textiles, fireproof fabrics, SiO₂ fibers

Deeprotect is keeping researching and developing the newest high performance material and products to meet the demands of the clients, for more tech. and products information, feel free to

contact us.

赣公网安备36072402000211号

赣公网安备36072402000211号